Manufacturing vinyl records

In 2010, after a guided tour through the factory in Haarlem, Ghislaine Pahnke explained again how vinyl records are made.

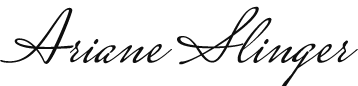

‘So how do you make a vinyl record? The provided audio is cut on the cutting lathe in a lacquer (a disc of aluminium coated with a layer of acetate) or DMM (a stainless steel disc coated with a copper layer). Using a cutting stylus (a diamond stylus for a DMM and a sapphire stylus for the lacquer), the audio is etched as a groove in the layer. The dynamics, the sound level, the audio spectrum, and the stereo width determine how deep the groove will ultimately be. For a record with two sides, two cuttings are made, for side A and side B.

In the cutting room – picture Ariane Slinger

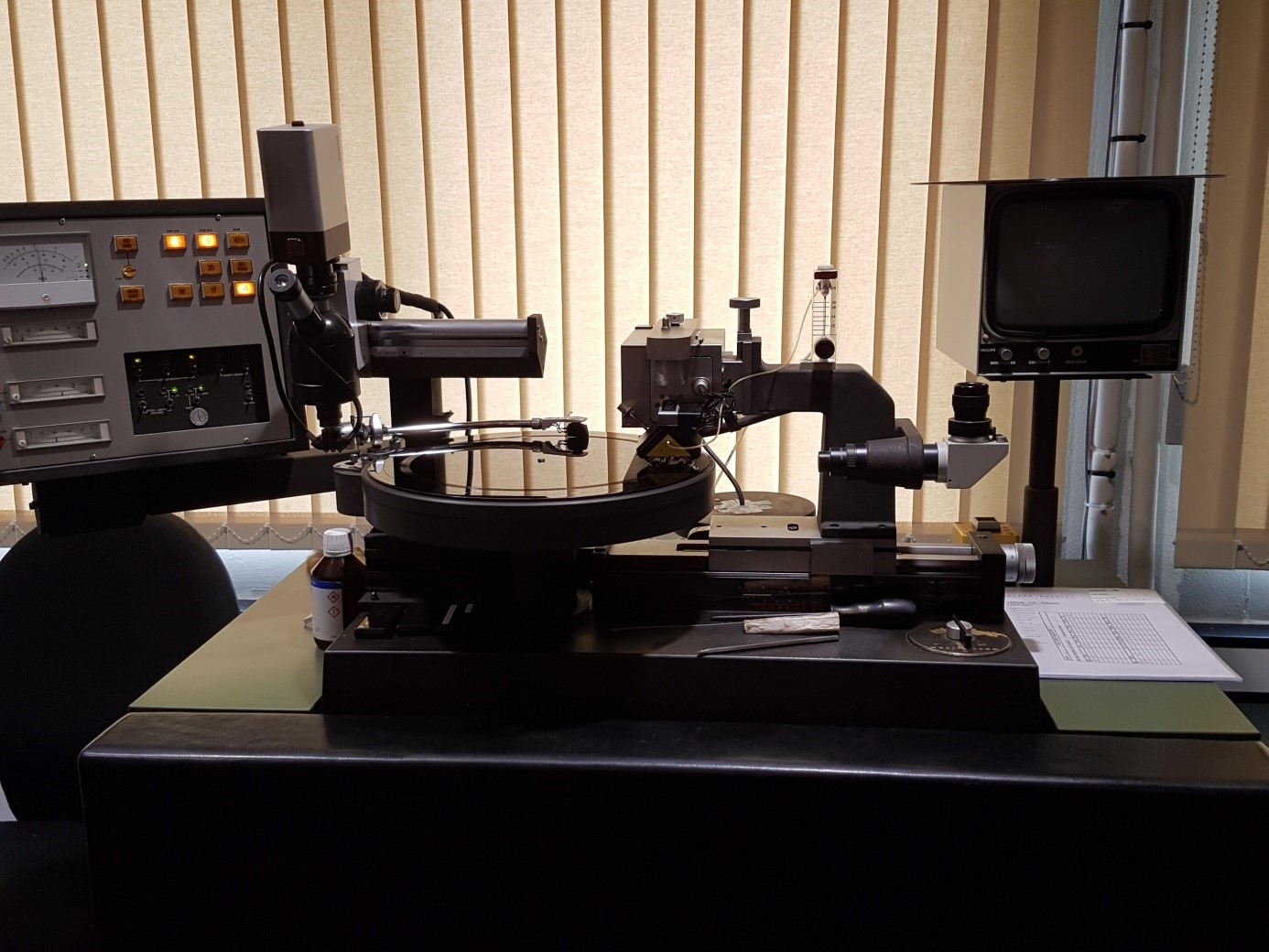

‘Then the stampers are pressed. Stampers are used to make the final records. To do this, the lacquer is sprayed with silver and then hung in a bath that uses electrolysis to adhere a layer of nickel to the silver. At a certain point this layer of nickel is thick enough to be pulled off the lacquer.

This process produces the first copy, the “negative”. The negative is again hung in a bath, and a layer of nickel is formed. This layer is the “positive”.

The positives- picture Ariane Slinger

The positives- picture Ariane Slinger

‘Then the positive is hung in a bath, and the layer this produces is the stamper. The stampers are put onto the press to press grooves into the vinyl. A set of stampers can produce 1,000 to 1,500 records. The vinyl is delivered in granular form and exposed to high temperatures and pressure to form a kind of paste, with is also called a “biscuit” or “puck”. This “biscuit” is placed between the stamper on the press, and in twenty seconds is pressed into a record. The record is then removed and the edges are trimmed. Once it is put into an inner sleeve, the record is set aside to cool down. Finally, the record is transported to the finishing department, where it is put into outer sleeves and provided with a sticker, insert, or plastic seal.’

[Alastair Philip Wiper – Inside The Biggest Vinly Pressing Plant In The World, The Netherlands /August 12, 2015]

[Youtube video – Our visit to Record Industry, one of world’s largest vinyl pressing plants !]

The biscuits – picture Ariane Slinger

The press – picture Ariane Slinger

Visit of the old ARTONE vinyl factory (now Record Industry)

with the Founding family SLINGER

(A personal memory of Harry Knipschild)

There is something fascinating and artistic about the making of a record. I well remember the first time I visited such a factory. It was 1964, and I was at Philips in Baarn together with Casper Koelman (Inelco). Right after we entered I heard ‘Little Red Rooster’ by the Rolling Stones for the first time. At full blast. They were working on turning the tape of the song (see above, the ‘audio’) into a lacquer disc. It seemed to me that this was all being done very professionally.

the Philips vinyl factory in Baarn – sky view

A bit further along in the building, I found myself in a large warm space with machines that reminded me of an industrial era I had thought was a thing of the past. The pressing of records did not strike me as particularly advanced. I encountered a similar situation some years later when I regularly visited Rien Duisterhof’s small pressing plant Cruquius on behalf of the record company Iramac – a similarly antiquated atmosphere where people were having a good time but working in factory-like conditions.

After 1973 – the first oil crisis, when the price of the raw materials (oil!) skyrocketed – I was allowed, as an employee of Polygram, to take a look inside the factory in Baarn. People were experimenting with ‘injection stampering’, a new method for making singles with fewer raw materials. Philips (Polygram) had implemented the use of robots. For some time, pressing the record and placing the newly pressed record in the album sleeve had been happening with virtually no human interference. I was extremely impressed. I also seem to remember that the albums were lighter because fewer materials had been used.

When in April of 2017 I was given a tour of Record Industry in Haarlem along with the Slinger family and my Greetje, it all felt familiar. In fact, everything that was happening was the same as nearly half a century earlier in Baarn.(

visit of Mrs Adriana Slinger at Record Industry, Casper Slinger’s widow – picture Ariane Slinger

Group’s picture, Ton and Mieke Vermeulen, Adriana Slinger, Ariane Slinger and husband Carlo Rosellini, Harry and Greetje Knipschild

No Comments